Ama-Helical Gearboxes

I-Plast extruder Gearbox

I-Gearbox ye-extruder yepulasitiki, abakhiqizi be-extruder gearbox, i-extruder gearbox iyathengiswa, ukulungiswa kwe-extruder gearbox, i-sterling extruder gearbox, i-twin screw extruder gearbox

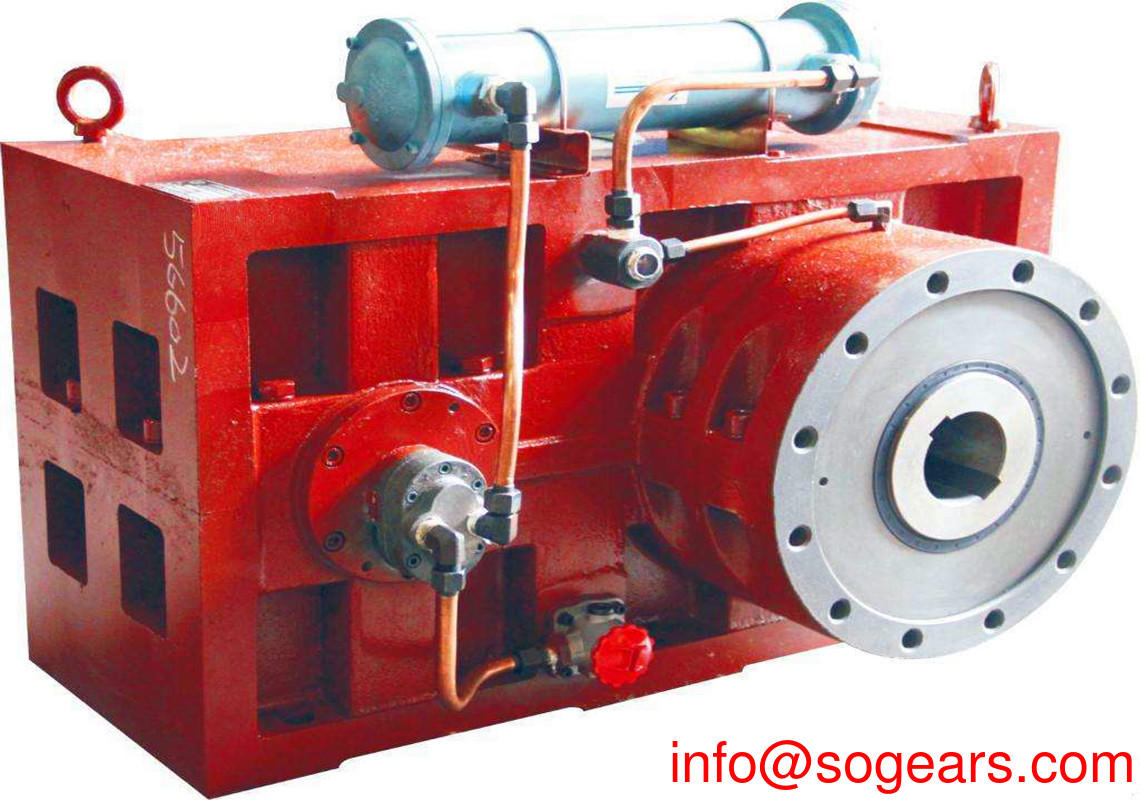

I-ZLYJ series i-hard surface gearbox iyingxenye yokudlulisa isihlalo esinembayo enamazinyo aqinile eklanyelwe isikulufu se-plastic extruder. Idizayini yomkhiqizo isebenzisa imininingwane yobuchwepheshe ecaciswe ku-JB/T8853-2001. Ifaka insimbi eqinile ye-alloy yamagiya nezingxenye ze-shaft. Igiya licutshungulwa ngokungcwatshwa kwe-carburizing, ukucisha nokugaya. Ukunemba kwegiya kungu-GB10095-88.6. Ubulukhuni bobuso bezinyo HRC54-62. I-thrust bear yosayizi oweqile ihlelwa ekugcineni kwe-shaft engenalutho ukuze imelane namandla asebenzayo e-axial yesikulufu. Izingxenye eziyinhloko ezijwayelekile njengama-bearings kanye ne-oil seals zenziwe ngemikhiqizo yasekhaya yezinga eliphezulu, futhi zingahlonyiswa ngemikhiqizo engenisiwe ngokuvumelana nezidingo zabasebenzisi. Wonke umshini unezici zevolumu encane, umthamo omkhulu wokuthwala, ukudluliselwa okuzinzile, umsindo ophansi nokusebenza kahle okuphezulu. Ukusebenza komkhiqizo kufinyelele ezingeni eliphezulu lamazwe ngamazwe.

Izici zomsebenzi:

Inhlanganisela yebhokisi kanye ne-thrust bear iphikisana namandla e-axial, futhi i-inferential bearing ihlelwa ekamelweni likawoyela le-gearbox ukuthuthukisa ukuthembeka kokusebenza.

Ukulungiswa okuncane kungasetshenziswa ukulungisa ibanga eliphakathi nendawo

Amandla okudlulisa aphezulu, angamelana ne-torque ephezulu namandla e-axial

I-Gearbox ekhethekile ye-extruder iyisakhi sokudlulisa esinomthamo omkhulu wezinyo eliqinile elinesihlalo esiklanywe ngokubhekisela emikhiqizweni yangaphandle efanayo ye-plastic screw extruder. Idizayini yomkhiqizo isebenzisa imininingwane yobuchwepheshe eshiwo yi-ZBJ19009-88. Izici zayo ukuthi amagiya kanye nezingxenye ze-shaft zenziwe ngensimbi ye-alloy high-strength, ecutshungulwa yi-carburizing, i-quenching nokugaya. Ukunemba kwegiya kungu-GB10095-88, ileveli 6. Ukuqina kwendawo yezinyo HRC54~62. I-thrust bear yosayizi omkhulu ihlelwa ekugcineni kwe-shaft engenalutho ukuze imelane ne-axial thrust yesikulufu. Wonke umshini unezinzuzo zevolumu encane, umthamo omkhulu wokuthwala, ukudluliselwa okuzinzile, umsindo ophansi nokusebenza kahle okuphezulu.

Izici ezikhethekile ze-Extruder Gearbox:

——Idizayini eyimojuli, ububanzi bokudlulisa nokusabalalisa okuhle nokunengqondo;

——Idizayini yomumo ifanele ukucushwa kokufakwa kwendawo yonke;

——Igiya ligaywa ngomshini wokugaya wegiya onembe kakhulu onokudluliswa okulinganiselwe, umsindo ophansi nokusebenza kahle okungama-98% phakathi kwezigaba;

Izimo ezisebenzayo zomshini wokukhipha i-Gearbox:

1. Ijubane le-high speed shaft ye-Gearbox alikho ngaphezu kuka-1500r/min.

2, izinga lokushisa lendawo yokusebenza ngu-0-35C. Uma izinga lokushisa lingaphezu kwemibandela, isisetshenziswa sokushisisa noma sokupholisa singalungiselelwa ngokwehlukana ngokwezidingo zomsebenzisi.

- Isingeniso

I-ZLYJ Plastic extruder Gearbox iwuhlobo lokuhlanganiswa kwegiya eliqinile elinemba kahle eliklanyelwe ngokukhethekile isikulufu esisodwa sepulasitiki/i-raba extruder. Ukuthatha i-JB/T 8853-2001 Cylindrical Plastic extruder Gearbox njengereferensi yokuklama, imikhiqizo isebenzisa insimbi ene-low-carbon alloy alloy enamandla aphezulu kumagiya kanye ne-gear shaft, eneflank yezinyo e-carbureted, ecishiwe futhi ephansi, ukuhlangabezana nokunemba kwegiya ku-Level 6 (GB/T 10095) kanye nokuqina izinyo flank HRC54~62. I-thrust bear enkulu igxunyekwe ngaphambili kwe-shaft yokukhiphayo ukuze ithwale i-thrust from the screw.

- Sebenzisa Ububanzi

- Ukuzungezisa okokufaka kwe-prime mover kuzoba ≤ 1500 rpm.

- Isivinini sokujikeleza kwegiya sizoba ≤ 20m/s.

- Izinga lokushisa elisebenzayo kufanele libe phakathi kuka -40 ℃ ~ 45 ℃. Shisisa uwoyela wokugcoba ube ngaphezu kuka-0℃ noma ukhethe amafutha okugcoba okushisa aphansi lapho izinga lokushisa lendawo lingaphansi kuka-0℃.

Qaphela:

- Ukuzungezisa kuyatholakala kokubili ukuya phambili nangemuva. Kodwa-ke, i-shaft enesivinini esiphezulu yezinye izinhlobo ze-Plastiki extruder Gearbox inepompo likawoyela elinendlela eyodwa eqondisa njengokuzenzakalelayo ku-shaft okukhiphayo ezungeza njengokuya kwewashi.

III. Plastic extruder Gearbox Izinhlobo

Ama-nameplates omkhiqizo: Lapho kulethwa, wonke ama-Gearbox e-Plastiki extruder anamathiselwe nama-nameplates ukuze kucaciswe uhlobo, amandla, idethi yokukhiqiza, inombolo yangaphambili yefekthri nezinye izici ngenjongo yokunakekela, ezingeke zisuswe noma nje.

- Ukufakwa kanye Nokuxhunywa kwe-Plastiki extruder Gearbox

- Qiniseka ukuthi isisekelo sokufaka se-Plastiki extruder Gearbox sisezingeni, sivikelekile futhi sizinzile. Beka ngokucophelela ukufakwa endaweni ekhethekile yokusebenza. Uma wonke amabhawodi okusetshenzwa kulengwa aqiniswe ngokulinganayo, qinisekisa ukuthi isikulufu esifakwe ku-shaft okukhiphayo siphenduka ngokukhululeka futhi njalo.

- Uxhumo lwesinxephezelo sephutha luzoba khona maqondana nokuxhunywa kwe-Plastiki extruder Gearbox kumhambisi oyinhloko. Qinisekisa ukugxila kwengxenye exhumayo ye-axial midline ye-Plastic extruder Gearbox's shaft yokufaka. Hlola ukuchezuka kwe-axial kanye nokugudluka kwe-angular, ukuchezuka kwakho okubili kuzoba ngaphakathi kwevelu evunyelwe yokuhlanganisa okusetshenzisiwe.

- Hlola ukuqina okwengeziwe kwe-radial shaft ye-Plastic extruder Gearbox ngokwesampula yomkhiqizo esimweni sokuthi isondo lebhande, igiya nesondo leketanga kusetshenziselwa ukufaka nokukhipha amandla okushayela e-Plastiki extruder Gearbox. Engxenyeni emaphakathi yeshafi yokufaka, amandla eradial engeziwe angeke abe ngaphezu kuka(N), lapho umzuzu wokufaka we-Plastiki extruder Gearbox (NM).

- Ngemva kokufaka, gcwalisa ku-Plastiki extruder Gearbox uwoyela wokugcoba uze ufike emgqeni omaphakathi wesikhombisi sikawoyela lapho usakaza ngokulinganayo.

- Xhuma futhi uvule uhlelo lokupholisa amanzi ukuze uhlole ukuthi amalunga ayopha noma ayavuza.

- Vula amandla ukuze uqalise okwesikhashana i-Plastic extruder Gearbox ngaphandle kokulayisha. Hlola ukuthi ipayipi lokuthambisa liyopha noma liyavuza yini, izingxenye nezingxenye ziyaxega futhi kuyenzeka noma yimuphi umsindo. I-Plastiki extruder Gearbox ingase inikezwe uma konke KULUNGILE.

ukunakwa:

◇ Sika futhi uvimbele (ngethegi eyisixwayiso, njll.) ukuxhunywa kabusha kwamandla kagesi enjini ngaphambi kokufaka ama-coupling.

◇ Ukushaya ngesando noma amanye amathuluzi afanayo akuvunyelwe uma ukhweza ama-coupling namagiya amancane ekugcineni kwe-shaft.

◇ Qinisekisa ukuthi ibhande liqine ngendlela efanele uma ufaka isondo lebhande.

◇ Ungafaki noma ungakhiphi isikulufu ngenkani maqondana nengxenye yokuphumayo.

◇ Ihood evikelayo izonikezwa ezingxenyeni ezizungezisayo zangaphandle ze-Plastiki extruder Gearbox (njenge-coupling, i-pulley yebhande, njll.).

◇ Susa kahle i-antirust, ukungcola noma amanye amabala ekugcineni kanye ne-flange ebusweni bomugqa wokuxhuma. I-Solvent ivunyelwe ukuhlanzwa kodwa izovinjelwa ukuthi ingagelezi iye ku-lip seal yezakhi zokuvala ze-shaft end.

- Ukusebenza kwe-Plastiki extruder Gearbox

Izivivinyo ngaphambi kokusebenza:

- Ngaphambi kokusebenza, hlola ukuthi i-Plastic extruder Gearbox inawo yini amafutha okugcoba ukuya ezingeni elifanele ngaphakathi kwayo. Yengeza uwoyela uma eshoda.

- Zonke izingxenye zokuxhuma zizovikeleka. Zonke izinto zokuvikela zizobe seziphelele.

- Hlola ukuthi imvelo ye-ambient ingaphansi kuka-0℃ yini, uma kunjalo, shisa ngaphambili amafutha okugcoba abe ngaphezu kuka-0℃.

Ukusebenza kwe-Plastiki extruder Gearbox:

- Qalisa i-Plastiki extruder Gearbox imizuzu engu-5~10 ngaphandle komthwalo (uma i-Plastiki extruder Gearbox ifakwe iphampu yegiya yenjini, qala iphampu kuqala) ukuze ugcobe amabheringi namagiya ngokufanelekile. Uma i-Plastic extruder Gearbox isetshenziswa okokuqala, ngemva kokusebenza kokungenzi lutho, engeza imithwalo isinyathelo ngesinyathelo ku-20% womthwalo olinganiselwe isikhathi ngasinye amahora angu-1~2 kuze kube yilapho umthwalo olinganiselwe ugcwele. Faka kusevisi uma konke kuhamba kahle.

- Ngesikhathi sokusebenza, qapha futhi ubhale phansi ngezikhathi ezithile ukunyuka kwezinga lokushisa kwe-Plastiki extruder Gearbox. Uma ukukhuphuka kwezinga lokushisa kwe-Plastic extruder Gearbox lingaphezu kuka-70℃ noma izinga lokushisa likawoyela lingaphezu kuka-100℃, misa i-Plastic extruder Gearbox ukuze uthole futhi uxazulule izinkinga. Xhumana nomnyango wethu wesevisi yangemuva kokuthengisa uma kunesidingo. Shintsha uwoyela wokugcoba ngaphambi kokuqala i-Plastiki extruder Gearbox futhi.

- I-Plastic extruder Gearbox izomiswa kanje: Vala i-hopper yokudla futhi, ngemva kokuba zonke izinto ezisebhakedeni sezikhishiwe, cisha ugesi oya ku-Plastiki extruder Gearbox (uma i-Plastic extruder Gearbox ifakwe igiya. iphampu yenjini, vala ipompo kuqala)

- Qalisa i-Plastic extruder Gearbox njalo emavikini angu-2 ukuya kwangu-3 uma kwenzeka ungenzi lutho isikhathi eside.

- Yenza izinyathelo zokulwa nokugqwala ngaphakathi nangaphandle kwe-Plastiki extruder Gearbox esimweni sokungenzi lutho ngaphezu kwezinyanga ezingu-6:

Gcwalisa uwoyela wokugcoba uze ugcwale, gcoba isiphetho se-shaft kanye nendawo engapendiwe ngezinto ze-wax ezilwa nokugqwala futhi uvikele ngokugcoba kokugcoba umlomo wezingxenye zokuvala ze-axle ngokumelene nokungena kwe-antirust.

ukunakwa:

◇ Phakathi nesigaba sokuqala sokusebenza, iphampu kawoyela ingase ibangele umsindo omkhulu ngenxa yokubonakala okuphezulu kwamafutha okugcoba kanye nokumelana nokumunca okukhulu kwephampu kawoyela, okungafa kancane kancane kanye nokukhuphuka kwezinga lokushisa lamafutha okugcoba.

◇ Uma iphampu kawoyela iba nomsindo omkhulu ngesikhathi sokusebenza okuvamile kwe-Plastiki extruder Gearbox, hlanza isihlungi sikawoyela ukuze ungenise ipayipi likawoyela.

◇ Gada ngezikhathi ezithile ukuvuza kwamafutha e-Plastiki extruder Gearbox phakathi nokusebenza kwayo, futhi, uma ikhona, misa i-Plastiki extruder Gearbox ukuze uxazulule inkinga.

- Ukulungisa nokunakekela

- Isikhathi sokuphumula sokulungiswa nokugcinwa

|

Isikhathi sokuphumula |

Ukulungisa nokunakekela |

|

Ukusebenza okujwayelekile |

Hlola izinga lokushisa lePlastiki i-extruder I-Gearbox: kungabi ngaphezu kuka-90 ℃ uma usebenzisa amafutha okugcoba amaminerali akukho ngaphezu kwe-100 ℃ uma usebenzisa amafutha okugcoba okwenziwa Hlola ukuthi ukhona yini umsindo ongajwayelekile we-Plastic extruder Gearbox Hlola ukuthi ingabe kukhona ukuvuza kwe-Plastic extruder Gearbox |

|

Ngemuva kokusebenza kwamahora angama-500 ~ 800 |

Okokuqala ukushintshwa kwamafutha okugcoba ngemva kokusebenza kokuqala Hlola izinga lamafutha ukuze unqume ukugcwaliswa kwamafutha |

|

Njalo ngemva kwamahora angu-3000, okungenani kanye ngonyaka |

Hlola uwoyela wokugcoba, futhi, esimweni sangaphandle noma esiswakeme, qinisekisa ukuthi okuqukethwe kwamanzi kuwoyela wokugcoba akumele kube ngaphezu kuka-500ppm. Faka esikhundleni samafutha okugcoba amaminerali (ihora lokusebenza ngaphansi kuka-8h ngosuku) Hlanza ipulaki yomoya |

|

Ngokwesimo sokusebenza, okungenani kanye izinyanga ezi-3 |

Faka esikhundleni samafutha okugcoba amaminerali (umsebenzi oqhubekayo wesikhathi eside) Hlola ukuthi kukhona yini ukuxebuka kwebhawudi elihlanganyelwe Hlola izimo zokungcola kanye nemishini yokugcoba neyokupholisa Hlanza isihlungi samafutha okugcoba bese ubuyisela umgogodla wokuhlunga uma kudingeka |

|

Ngokwesimo sokusebenza, okungenani kanye ngonyaka |

Faka esikhundleni samafutha okugcoba okwenziwa |

|

Njengokwemvelo kanye nesimo sokusebenza |

Thuthukisa noma shintsha upende ovikelayo (ongagqwali) ongaphezulu Hlanza ingaphandle kanye ne-Plastiki extruder Gearbox Hlola izisetshenziswa ezifakiwe |

- Isikhawu sesikhathi sokushintshwa kwamafutha okugcoba

Shintshanisa njalo amafutha okugcoba ohlobo olukhethekile lwe-Plastic extruder Gearbox esebenza endaweni enzima. Isibalo esingezansi sibonisa isikhawu sesikhathi sokushintshwa kwamafutha okugcoba endaweni evamile. I-CLP HC ibhekisela kuwoyela wokugcoba wokwenziwa we-PAO.

(1) Isikhathi sokusebenza (2) Izinga lokushisa eliqhubekayo kubhavu kawoyela (isilinganiso senani elingu-70℃)

VII. Ukuhlaziywa Kwephutha Nezixazululo

|

Amaphutha |

Izimbangela |

Solutions |

|

Amaphutha |

Izimbangela |

Solutions |

|

Umsindo wokusebenza ongavamile novamile |

A. Umsindo wokugingqika/wokugaya: ukuthwala konakele B. Umsindo wokungqongqoza: ukugijima okungalingani |

A. Hlola uwoyela wokugcoba bese ushintsha i-bearing B. Xhumana no-Guomao |

Ukuvuza kwamafutha okugcoba: Indawo ehlanganisiwe ye-Plastiki extruder Gearbox Qeda indawo yekhava ye-Plastiki extruder Gearbox Isembozo sombobo wePlastiki extruder Gearbox Iphoyinti lokuvala le-drive shaft Ipulaki yokukhipha uwoyela Ipulaki yomoya |

Ukuxegiswa kwezingxenye zokuxhuma ze-Plastiki extruder Gearbox Ukuxegiswa kwe-fastener yokuxhuma Ukufakwa okungalungile kwezingxenye zokuvala Ukulimala/ukuhuzuka kwezingxenye zokuvala Ukuxhumeka okuvulekile Izinga likawoyela eliningi kakhulu lamafutha okugcoba Ukufakwa okungalungile |

Hlola amabhawodi axhumayo bese uqinisa lawo axegayo uma kudingeka Hlola ingxenye yokuvala bese uyishintsha uma kudingeka Hlola izinga likawoyela/ thuthukisa ukukhathala Xhumana no-Guoma |

|

|

Umsindo wokusebenza ongajwayelekile nongajwayelekile |

Ukungcola kwamafutha okugcoba |

Bheka uwoyela wokugcoba, yeka ukusebenza bese uthinta uGuomao |

||||

|

Umsindo ongajwayelekile ezingxenyeni ezingashintshi ze-Plastic extruder Gearbox |

I-Fastener ye-Plastic extruder Gearbox iyaxega |

Hlola ama-fasteners futhi usebenzise lawo ashiwo |

||||

|

Izinga lokushisa eliphezulu kakhulu lokusebenza |

A. Ngamafutha amaningi okugcoba B. Ukuguga kanye nokuwohloka kwamafutha okugcoba C. Ukungcola okuningi emafutheni okugcoba D. Ukulimala kwephampu yokugcoba E. Iphutha lesistimu yokupholisa |

A. Hlola izinga likawoyela bese wenza ukuguqulwa uma kudingeka B. Hlola isikhathi sokushintshwa kwamafutha okugcoba C. Hlola amafutha okugcoba D. Hlola iphampu yokugcoba bese uyishintsha E. Hlola uhlelo lokupholisa |

Izinga lokushisa eliphezulu kakhulu kubhere |

A. Amafutha okugcoba anganele B. Ukuguga kanye nokuwohloka kwamafutha okugcoba C. Ukulimala kwepompo yokugcoba D. Ukulimala kokuzala |

A. Hlola izinga likawoyela bese wenza ukuguqulwa uma kudingeka B. Hlola isikhathi sokushintshwa kwamafutha okugcoba C. Hlola iphampu yokugcoba bese uyishintsha D Hlola ukuma bese uyishintsha |

|

|

Izinga lokushisa eliphakeme kakhulu endaweni yokuvala shaft igcina ngesikhathi sokusebenza |

Ukuhlanzwa okunganele kokuxhumeka kokuphela kwe-shaft ngesikhathi sokufakwa Ukugijima kwezingxenye zokuvala kanye nokuphela kwe-shaft |

Hlanza ukuphela kwe-shaft Kubheke njengokujwayelekile Xhumana no-Guoma |

Lapho uxhumana noGuomao, sicela unikeze imininingwane elandelayo:

|

Qedela idatha ku-nameplate |

- |

Izinhlobo nobubanzi bamaphutha |

- |

Isikhathi nezimo zamaphutha zenzeka |

- |

Izimbangela |

VIII. Ukukhetha Amafutha Okugcoba

I-viscosity yamafutha okugcoba izonqunywa ngokuhambisana nesivinini se-peripheral V, indawo yokusebenza noma indlela yokugcoba yamagiya anesivinini esikhulu:

Lapho izinga lokushisa elingu-V≤2.5m/s noma lendawo lingaphakathi kuka-35℃~50℃, khetha uwoyela wegiya ovaliwe wezimboni we-CKC320 noma i-CKD320 uwoyela osindayo wezimboni ovaliwe wegiya;

Lapho kufakwa i-V>2.5m/s noma ukuthambisa okujikelezayo okuphoqelelwe kusetshenziswa, khetha uwoyela wegiya ovaliwe wezimboni we-CKC220 noma i-CKD220 uwoyela wegiya osindayo wezimboni.

I-lubricant

Igrisi yokuthambisa ayinconywa nge-Plastic extruder Gearbox. Xhumana nathi uma kudingeka.

Bheka Isijobelelo-Ithebula Lokuqhathanisa Amafutha Okugcoba emikhiqizweni kawoyela wokugcoba wangaphakathi nangaphandle

- Izingxenye Zokugqoka

Uhlu Lwezingxenye Zokugqoka Ze-Plastiki extruder Gearbox

Uhlu lokupakisha lwe-Gearbox ye-Plastiki extruder

Isijobelelo - Ithebula Lokuqhathanisa Amafutha Okugcoba (Amafutha Okugcoba Amaminerali):

|

Isigaba |

I-ISOVG |

I-AGMA |

Umthengisi |

Uhlobo Lwamafutha Okugcoba |

I-Viscosity / 40 ℃ |

Indawo ebandayo ℃ |

|

Isigaba |

I-ISOVG |

I-AGMA |

Umthengisi |

Uhlobo Lwamafutha Okugcoba |

I-Viscosity / 40 ℃ |

Indawo ebandayo ℃ |

|

220 |

220 |

5EP |

Disemba |

I-Degol BG220 |

220 |

-21 |

320 |

320 |

6EP |

Disemba |

I-Degol BG320 |

320 |

-18 |

|

|

BP |

I-Energol GR-XP220 |

210 |

-27 |

BP |

I-Energol GR-XP320 |

305 |

-24 |

|||||||

|

UCastrol |

I-Alpha SP220 |

220 |

-21 |

UCastrol |

I-Alpha SP320 |

320 |

-21 |

|||||||

|

UCastrol |

I-Alphamax 220 |

220 |

-24 |

UCastrol |

I-Alphamax 320 |

320 |

-18 |

|||||||

|

I-Chevron |

I-Industrial Oil EP220 |

220 |

-12 |

I-Chevron |

I-Industrial Oil EP320 |

320 |

-9 |

|||||||

|

unkulunkulukazi |

I-Falcon CLP220 |

220 |

-18 |

unkulunkulukazi |

I-Falcon CLP320 |

320 |

-18 |

|||||||

|

Esso |

I-Spartan EP220 |

226 |

-30 |

Esso |

I-Spartan EP320 |

332 |

-27 |

|||||||

|

I-Exxon |

I-Spartan EP220 |

226 |

-30 |

I-Exxon |

I-Spartan EP320 |

332 |

-27 |

|||||||

|

Ama-Fuchs |

I-Renolin CLP220 Plus |

223 |

-23 |

Ama-Fuchs |

I-Renolin CLP320 Plus |

323 |

-21 |

|||||||

|

IGhuba |

I-Gulf EP Lubricant HD220 |

219 |

-19 |

IGhuba |

I-Gulf EP Lubricant HD320 |

300 |

-12 |

|||||||

|

Klüber |

I-Klüberoil GEM 1-220 |

220 |

-15 |

Klüber |

I-Klüberoil GEM 1-320 |

320 |

-15 |

|||||||

|

Kuwait |

Q8 Goya 220 |

220 |

-21 |

Kuwait |

Q8 Goya 320 |

320 |

-18 |

|||||||

|

mobile |

I-Mobilgear 630 |

207 |

-18 |

mobile |

I-Mobilgear 632 |

304 |

-18 |

|||||||

|

mobile |

I-Mobilgear XMP 220 |

220 |

-24 |

mobile |

I-Mobilgear XMP 320 |

320 |

-18 |

|||||||

|

I-Molub-Alloy |

MA-90/220 |

220 |

-18 |

I-Molub-Alloy |

MA-90/320 |

320 |

-15 |

|||||||

|

I-Optimol |

I-Optigear BM220 |

233 |

-15 |

I-Optimol |

I-Optigear BM320 |

338 |

-15 |

|||||||

|

Petro Canada |

Ultima EP220 |

223 |

-30 |

Petro Canada |

Ultima EP320 |

320 |

-21 |

|||||||

|

shell |

Amafutha e-Omala F220 |

220 |

-21 |

shell |

Amafutha e-Omala F320 |

320 |

-18 |

|||||||

|

I-Texaco |

Inani eliphakeme kakhulu lama-220 |

209 |

-21 |

I-Texaco |

Inani eliphakeme kakhulu lama-320 |

304 |

-18 |

|||||||

|

Ubude |

I-Carter EP220 |

220 |

-12 |

Ubude |

I-Carter EP320 |

320 |

-12 |

|||||||

|

I-Tribol |

I-Tribol 1100/220 |

222 |

-25 |

I-Tribol |

I-Tribol 1100/320 |

317 |

-23 |

|||||||

|

GB5903-95 |

Domestic |

I-CKC220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Domestic |

I-CKC320 |

288 ~ 352 |

≤-8 |

|||||

|

GB5903-95 |

Domestic |

CKD220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Domestic |

CKD320 |

288 ~ 352 |

≤-8 |

|||||

Isijobelelo - Ithebula Lokuqhathanisa Kawoyela Wokuthambisa (I-PAO Synthetic Lubricating Oil):

|

Isigaba |

I-ISOVG |

I-AGMA |

Umthengisi |

Uhlobo Lwamafutha Okugcoba |

I-Viscosity cSt |

Indawo ebandayo ℃ |

|

Isigaba |

I-ISOVG |

I-AGMA |

Umthengisi |

Uhlobo Lwamafutha Okugcoba |

I-Viscosity cSt |

Indawo ebandayo ℃ |

||

|

40 ℃ |

100 ℃ |

40 ℃ |

100 ℃ |

|||||||||||||

|

220 |

220 |

5EP |

unkulunkulukazi |

Idatha ye-HCLP220 |

220 |

25.1 |

-36 |

320 |

320 |

6EP |

unkulunkulukazi |

Idatha ye-HCLP320 |

320 |

33.9 |

-33 |

|

|

Esso |

I-Spartan Synthetic EP220 |

232 |

26.5 |

-39 |

Esso |

I-Spartan Synthetic EP320 |

328 |

34.3 |

-36 |

|||||||

|

I-Exxon |

I-Spartan Synthetic EP220 |

232 |

26.5 |

-39 |

I-Exxon |

I-Spartan Synthetic EP320 |

328 |

34.3 |

-36 |

|||||||

|

Ama-Fuchs |

I-Renolin Unisyn CLP220 |

221 |

25.8 |

-42 |

Ama-Fuchs |

I-Renolin Unisyn CLP320 |

315 |

33.3 |

-39 |

|||||||

|

Klüber |

I-Klübesynth EG 4-220 |

220 |

26 |

-40 |

Klüber |

I-Klübesynth EG 4-320 |

320 |

38 |

-40 |

|||||||

|

mobile |

I-Mobilgear SHC XMP 220 |

220 |

28.3 |

-45 |

mobile |

I-Mobilgear SHC XMP 320 |

320 |

37.4 |

-39 |

|||||||

|

mobile |

I-Mobilgear SHC 220 |

213 |

26 |

-51 |

mobile |

I-Mobilgear SHC 320 |

295 |

34 |

-48 |

|||||||

|

I-Optimol |

I-Optigear Synthic A220 |

210 |

23.5 |

-36 |

I-Optimol |

I-Optigear Synthic A320 |

290 |

30 |

-36 |

|||||||

|

shell |

I-Omala Oil HD220 |

220 |

25.5 |

-48 |

shell |

I-Omala Oil HD320 |

320 |

33.1 |

-42 |

|||||||

|

I-Texaco |

I-Pinnacle EP220 |

220 |

25.8 |

-48 |

I-Texaco |

I-Pinnacle EP320 |

320 |

35.2 |

-39 |

|||||||

|

Ubude |

I-Carter EP/HT220 |

220 |

25 |

-39 |

Ubude |

I-Carter EP/HT320 |

320 |

33 |

-36 |

|||||||

|

I-Tribol |

I-Tribol 1510/220 |

220 |

24.6 |

-42 |

I-Tribol |

I-Tribol 1510/320 |

330 |

33.2 |

-39 |

|||||||

|

I-Tribol |

I-Tribol 1710/220 |

220 |

- |

-33 |

I-Tribol |

I-Tribol 1710/320 |

320 |

- |

-30 |

|||||||

|

Domestic |

Udonga Olukhulu |

4405/220 |

221.3 |

- |

-42 |

|

|

|

|

|

|

|||||

|

Domestic |

Udonga Olukhulu |

4406/220 |

225.3 |

- |

-42 |

Domestic |

Udonga Olukhulu |

4406/320 |

330.5 |

- |

-40 |

|||||

Isimiso esisodwa sokukhipha isikulufu esisodwa

Isikulufa esisodwa kwesinye isikhathi sihlukaniswe izigaba ezintathu ngobude obusebenzayo. Ukusebenza okusebenzayo kwalezi zingxenye ezintathu kunqunywa ngokusho kobubanzi besibazi nokubekwa kwesikulufa. Ngokuvamile, ihlukaniswe ingxenye eyodwa kwezintathu.

Intambo yokugcina yechweba lempahla ibizwa ngokuthi isigaba sokudlulisa: impahla iyadingeka ukuze yenziwe ipulasitiki lapha, kodwa kufanele ishiswe futhi ihlanganiswe. Esikhathini esedlule, inkolelo-mbono endala ye-extrusion yayikholelwa ukuthi izinto ezikhona lapha zazikhululekile, futhi kamuva zafakazela ukuthi indaba lapha empeleni Ipulaki eqinile, okusho ukuthi, into ekhona lapha iqinile njengepulaki ngemva kokucindezelwa, ngakho-ke umsebenzi wayo inqobo nje uma umsebenzi wokudlulisa usuphothuliwe.

Ingxenye yesibili ibizwa ngokuthi yi-compression section. Ngalesi sikhathi, ivolumu ye-groove iyancipha kancane kancane isuka enkulu iye enkulu, futhi izinga lokushisa lifinyelela izinga le-plasticization yezinto. Lapha, ukucindezelwa kukhiqizwa isigaba sesithathu sokudlulisa, lapho kucindezelwa khona kuya kwesinye, okubizwa ngokuthi isilinganiso sokucindezelwa kwesikulufu -- 3:1, eminye imishini nayo ishintshile, futhi izinto ezenziwe ngepulasitiki eziqediwe zingena esigabeni sesithathu.

Isigaba sesithathu yisigaba sokulinganisa, lapho impahla igcina khona amazinga okushisa eplastiki, ngokunemba nangokucacile futhi idlulisa izinto ezincibilikisiwe njengoba ne-metering pump yokuhlinzeka ikhanda, ngaleso sikhathi izinga lokushisa alikwazi ukuba phansi kunogesi wokushisa weplastiki, ngokuvamile ophakeme kancane .

Umhleli wokonga amandla we-Extruder

Ukonga amandla we-extruder kungahlukaniswa izingxenye ezimbili: enye yingxenye yamandla kanti enye ingxenye yokushisa.

Ukulondolozwa kwamandla: Kusetshenziswa iningi lama-inverters. Indlela yokonga amandla ukusindisa amandla asele e-motor. Isibonelo, amandla wangempela wemoto yi-50Hz, futhi udinga kuphela i-30Hz ekukhiqizeni ukukhiqiza okwanele. Ukusetshenziswa kwamandla ngokweqile akulutho. Kuhlukumezekile, i-inverter ukushintsha ukuphuma kwamandla emotri ukufeza ukonga amandla.

Ukonga amandla engxenyeni yokufudumeza: Iningi lokonga amandla ekufudumaleni longa amandla yi-heater kagesi, futhi isilinganiso sokugcina amandla cishe singama-30% ~ 70% wendandatho eyindilinga endala.

inqubo yokusebenza

Izinto zepulasitiki zingena kwi-extruder zisuka kwi-hopper, futhi zihanjiswa phambili ngokujikeleza kwesikulufa. Ngesikhathi sokuqhubekela phambili, okubhalwe phansi kuyashiswa ngumgqomo, kukalwa isikali bese kufakwa ingcindezi ukuze kuncibilike impahla. Ngakho-ke, ushintsho phakathi kwezifunda ezintathu zombuso ophethe ingilazi, izwe eliphakeme kakhulu, kanye nesimo sokugeleza kwe-viscous siyatholakala.

Endabeni yengcindezelo, impahla esezingeni lokugeleza kwe-viscous idluliswa kufiwa inesimo esithile, bese iba yinto eqhubekayo enesiphambano nokubonakala komlomo kufana nokufa. Kuyabe sekupholiswa futhi kwakhiwa ukwakha isimo esinengilazi, ngaleyo ndlela sithola leyo ngxenye ukuthi icutshungulwe.

Umhleli wokuqamba

Ku-extruder, ngokuvamile, eyisisekelo futhi eguquguqukayo kakhulu i-screw extruder eyodwa. Ihlanganisa ikakhulukazi: izingxenye eziyisithupha: ukudluliselwa, idivayisi yokudla, umgqomo, isikulufu, ikhanda lomshini kanye nokufa.

Isigaba sokuhambisa

Ingxenye yokudlulisela imvamisa yakhiwa injini kagesi, ibhokisi legiya lokunciphisa namabheringi. Phakathi nenqubo ye-extrusion, isivinini se-screw kumele sizinze futhi asikwazi ukushintsha ngokushintsha komthwalo wesikulufu, ukuze kugcinwe ikhwalithi efanayo yomkhiqizo otholiwe. Nokho, ezikhathini ezihlukene, isikulufu singadingeka ukuthi sigudluzwe ukuze kuzuzwe imfuneko yokuthi idivayisi eyodwa ingakhipha amapulasitiki ahlukene noma imikhiqizo ehlukene. Ngakho-ke, le ngxenye ngokuvamile isebenzisa i-AC commutator motor, motor DC namanye amadivaysi ukuze kuzuzwe ushintsho lwesivinini esingenasinyathelo, isivinini esijwayelekile sesikulufa singu-10~100 rev / min.

Umsebenzi wesistimu yokudlulisa ukushayela isikulufu, esihlinzeka nge-torque nesivinini esidingwa isikulufu ngesikhathi senqubo yokukhipha, ngokuvamile ehlanganisa injini, i-Gearbox kanye ne-bearing. Ngaphansi kwesisekelo sokuthi isakhiwo siyefana ngokuyisisekelo, izindleko zokukhiqiza ze-Gearbox zicishe zilingane nobukhulu bayo bangaphandle nesisindo. Ngenxa yokuthi umumo nesisindo se-Gearbox kukhulu, kusho ukuthi ziningi izinto ezisetshenziswayo ngesikhathi sokukhiqiza, nama-bearings asetshenziswayo nawo makhulu uma kuqhathaniswa, okwandisa izindleko zokukhiqiza.

Idivayisi yokondla

Iningi lama-feedstocks li-pelletized, kodwa ama-strips noma ama-powders nawo angasetshenziswa. Izinto zokushaja ngokuvamile zisebenzisa i-conical hopper enesidingo sevolumu okungenani ihora elilodwa. Idivayisi yokuvala ihlinzekwa ngaphansi kwe-hopper ukuze ilungise futhi isike ukugeleza, futhi imbobo yokubona kanye nedivayisi yokulinganisa kufakwa eceleni kwe-hopper. Amanye ama-hopper angase futhi abe nomshini wokukhulula ukucindezela noma okokushisisa okuvimbela isitokwe sokudla ekumunceni umswakamo ovela emoyeni, noma amanye ama-cartridges nawo angaba ne-agitator yawo yokuphakela ngokuzenzakalelayo noma ukuphakela.

hopper

I-hopper ngokuvamile yenziwa ngendlela elinganayo. Iwindi livulwa ohlangothini lwe-hopper ukuze kubhekwe izinga lempahla kanye nesimo sokudla. Iphansi le-hopper linomnyango ovulayo novalayo wokumisa futhi ulungise inani lokuphakelayo. Vala ingaphezulu le-hopper ukuze uvimbele uthuli, umswakama kanye nokungcola ukuthi kuwele kuyo. Uma ukhetha ukwaziswa kwe-hopper, kungcono kakhulu ukusebenzisa izinto ezingasindi, ezimelana nokugqwala futhi kulula ukuzisebenzisa umshini, ngokuvamile zisebenzisa i-aluminium namapuleti ensimbi engagqwali. Umthamo we-hopper uncike kusayizi we-extruder kanye nendlela yokulayisha. Ngokuvamile, inani le-extrusion le-extruder lisuka ku-1 kuya ku-1.5 amahora.

Kunezinhlobo ezimbili zezindlela zokuphakela: ukuphakela mathupha kanye nokudla okuzenzakalelayo. Ukuphakela okuzenzakalelayo ikakhulukazi kufaka phakathi ukuphakelwa kwentwasahlobo, ukuphakelwa kwe-blast, ukuphakela nge-vacuum, ukudlulisa ibhande lokudlulisa nokunye. Ngokuvamile, ama-extruder amancane alayishwa ngesandla futhi ama-extruder amakhulu alayishwa ngokuzenzakalelayo.

Ukuhlukaniswa kwezindlela zokudla

1 Ukudla kwe-Gravity:

Isimiso - Impahla ingena emgqonyeni ngesisindo sayo, okuhlanganisa ukuphakelwa mathupha, ukuphakelwa kwentwasahlobo, kanye nokuqhunyiswa.

Izici - isakhiwo esilula kanye nezindleko eziphansi. Nokho, kulula ukubangela ukudla okungalingani, okuthinta izinga lezingxenye. Ilungele kuphela ama-extruder amancane.

2 Ukondla ngenkani:

Isimiso - Faka idivayisi ku-hopper efaka ukucindezela kwangaphandle kokubalulekile, okuphoqelela okubalulekile emgqonyeni we-extruder.

Izici - zinganqoba "ibhuloho" lomkhuba, ukuze ukudla kulingane. Isikulufu sokuphakelayo sishayelwa isikulufu se-extruder ngeketango lokushayela ukuze silungise isivinini saso siye kusivinini sesikulufu. Idivayisi yokuvikela ukulayishwa ngokweqile ingenziwa isebenze lapho imbobo yesiphakeli ivinjiwe, ngaleyo ndlela kugwenywe ukulimala kudivayisi yokuphakela.

igobolondo

Ngokuvamile, umphongolo wensimbi owenziwe ngensimbi ye-alloy noma ipayipi yensimbi eyinhlanganisela ehlanganiswe nensimbi ye-alloy. Izici zayo eziyisisekelo ukushisa okuphezulu nokumelana nokucindezela, ukugqoka okuqinile nokumelana nokugqwala. Ngokuvamile, ubude bomphongolo buphindwe izikhathi ezingu-15 kuya kwezingu-30 ububanzi bawo, futhi ubude bukhulu kangangokuthi impahla ishisa ngokwanele futhi yenziwe ngepulasitiki ngokufanayo. Umgqomo kufanele ube nokuqina okwanele nokuqina. Ingaphakathi kufanele libe bushelelezi, kodwa eminye imiphongolo iqoshwe ngemisele ehlukahlukene ukuze kwandiswe ukungqubuzana kwepulasitiki. Izifudumezi zikagesi, amadivaysi okulawula izinga lokushisa kanye nezinhlelo zokupholisa zinikezwa ngaphandle komgqomo ngama-resistors, ama-inductors nezinye izindlela zokushisa.

Kunezinhlobo ezintathu zezinto ezibonakalayo emgqonyeni:

(1) umgqomo obalulekile

Indlela yokucubungula - icutshungulwe kuyo yonke into.

Izinzuzo - kulula ukuqinisekisa ukunemba okuphezulu kokukhiqiza kanye nokunemba komhlangano, kungenza umsebenzi womhlangano ube lula, isilinda sishiswa ngokulinganayo, kanye nezinhlelo zokusebenza eziningi.

Ukungalungi - Ngenxa yobude bomgqomo omkhulu kanye nezidingo eziphezulu zokucubungula, izidingo zemishini yokucubungula nazo ziqinile kakhulu. Ubuso obungaphakathi bomgqomo kunzima ukulungisa ngemva kokugqoka.

(2) Inhlanganisela yezinto

Indlela yokucubungula - umgqomo ucutshungulwa ngezigaba eziningana, bese izigaba zixhunywe ngama-flange noma ezinye izinhlobo.

Izinzuzo - ukucubungula okulula, kulula ukuguqula i-aspect ratio, esetshenziswa kakhulu ukushintsha i-aspect ratio ye-screw.

Ukungalungi - izidingo eziphezulu zokunemba kokucubungula, ngenxa yezingxenye eziningi, kunzima ukuqinisekisa ukuthi i-coaxiality yengxenye ngayinye, uxhumano lwe-flange lwephula ukufana kokushisa komgqomo, kwandisa ukulahlekelwa ukushisa, izilungiselelo zokushisa nokupholisa kanye nokugcinwa kwesistimu Kunzima nakakhulu.

(3) Umgqomo weBimetallic

Indlela yokucubungula - Inlay noma uphonsa ungqimba lwensimbi ye-alloy ngaphakathi kwesisekelo se-carbon steel evamile noma insimbi ecijile. Ayigcini nje ngokuhlangabezana nezidingo ezibonakalayo zomgqomo, kodwa futhi igcina izinto eziyigugu zensimbi.

1 I-Bushing cartridge: I-cartridge ifakwe i-alloy steel bushing eshintshwayo. Ukulondoloza izinsimbi eziyigugu, ama-bushings angashintshwa, futhi ukuphila komgqomo kwanda. Kodwa ukuklama kwayo, ukukhiqiza kanye nokuhlanganisa kuyinkimbinkimbi kakhulu.

2 Umgqomo wokuphonsa: Ungqimba olucishe lube ngu-2 mm ubukhulu bengxubevange luphonswa nge-centrifugally odongeni lwangaphakathi lomgqomo, bese ububanzi obungaphakathi obudingekayo bomphongolo butholwa ngokugaya. Isendlalelo se-alloy siboshwe kahle esisekelweni somphongolo, futhi ukubopha ngobude be-axial bomphongolo kufana ngokufanayo, akunaso ukuthambekela kokuxebuka, akuqhekeki, kunokusebenza okuhle kakhulu kokushelela, futhi kunokumelana nokugqoka okuphezulu. impilo ende.

1) I-longitudinal groove yodonga lwangaphakathi lwesigaba sokuphakela umgqomo ivuliwe

Ukuze kwandiswe izinga lokuthutha okuqinile, enye indlela iwukwandisa i-coefficient of friction of the surface of the cylinder by solid transport theory. Enye indlela ukukhulisa indawo yento embotsheni yokuphakelayo ngokusebenzisa ingxenye ephambanayo perpendicular to the screw axis. Ukwakhiwa kwe-longitudinal groove odongeni lwangaphakathi lwesigaba sokuphakela umgqomo kanye ne-taper yodonga lwangaphakathi lwesigaba sesigaba sokudla eduze kwechweba lokuphakela yizici zezindlela ezimbili.

2) Umphongolo wesigaba sokuphakelayo sokupholisa ngempoqo

Kukhona nendlela yokwandisa inani lezinto eziqinile ezithuthwayo. Kuwukupholisa umphongolo wesigaba sokuphakela, inhloso ukugcina izinga lokushisa lezinto okufanele zidluliselwe ngaphansi kwendawo yokuthambisa noma indawo yokuncibilika, ukugwema ukubukeka kwefilimu encibilikayo ukuze kugcinwe impahla eqinile yokungqubuzana kwezinto.

Ngendlela engenhla, ukusebenza kahle kokudlulisa kukhuphuka kusuka ku-0.3 kuya ku-0.6, futhi inani le-extrusion alizwani kakhulu nezinguquko ekucindezelweni kwekhanda.

Isikulufu siyinhliziyo ye-extruder futhi siyingxenye eyinhloko ye-extruder. Ukusebenza kwesikulufu kunquma ukukhiqiza, ikhwalithi yokwenza ipulasitiki, ukuhlakazwa kwesigcwalisi, izinga lokushisa elincibilikayo, ukusetshenziswa kwamandla, njll. kwe-extruder. . Iyingxenye ebaluleke kakhulu ye-extruder, engathinta ngokuqondile uhla lwesicelo kanye nokusebenza kahle kokukhiqiza kwe-extruder. Ukuzungezisa kwesikulufu kusebenzisa ingcindezi enkulu kupulasitiki. Ipulasitiki inganyakaza, icindezele futhi ithole ukushisa okuthile ekungqubuzaneni kwesilinda. Ipulasitiki ixutshwe futhi yenziwe ipulasitiki ngesikhathi sokuhamba kwesilinda, futhi isimo sokugeleza kwe-viscous I-melt ibunjwa ngenkathi ikhishwa ukuze igeleze ku-die ukuze ithole umumo oyifunayo. Njengomphongolo, isikulufu naso senziwe ngamandla aphezulu, ukushisa kanye nengxubevange engagqwali.

Ngenxa yezinhlobonhlobo zamapulasitiki, izakhiwo zabo nazo zihlukile. Ngakho-ke, ekusebenzeni kwangempela, ukuze uvumelane nezidingo ezahlukene zokucubungula ipulasitiki, izinhlobo zezikulufu ezidingekayo zihlukile, futhi izakhiwo nazo zihlukile. Ukuze kwandiswe ukusebenza kahle kwamapulasitiki ukuze kwandiswe ezokuthutha, ukukhishwa, ukuxuba kanye ne-plasticization.

Isithombe sibonisa izikulufu ezimbalwa ezivamile. Amapharamitha ayisisekelo abonisa izici zesikulufu ahlanganisa lokhu okulandelayo: ububanzi, i-aspect ratio, isilinganiso sokuminyanisa, iphimbo, ukujula kwegroove, i-helix angle, ukucaciswa kwesikulufu nomgqomo, nokunye okunjalo. I-screw diameter D evame kakhulu icishe ibe ngu-45 kuya ku-150 mm. Njengoba i-diameter yesikulufu ikhula, umthamo wokucubungula we-extruder uyakhula ngokufanele, futhi ukukhiqiza kwe-extruder kuhambisana nesikwele se-diameter yesikulufu D. Isilinganiso sobude obusebenzayo kuya kububanzi bengxenye yokusebenza yesikulufu (okubhekiselwe kuso kuya njenge-aspect ratio, evezwa njenge-L/D) ngokuvamile i-18~25. I-L/D enkulu ingathuthukisa ukusatshalaliswa kwezinga lokushisa kwezinto, yenze kube lula ukuxutshwa nokufakwa kwepulasitiki kwamapulasitiki, futhi kunciphise ukuvuza nokubuyela emuva.

Thuthukisa umthamo wokukhiqiza we-extruder, isikulufu esikhulu se-L/D sinokuvumelana nezimo okuqinile futhi singasetshenziselwa ukukhishwa kwamapulasitiki ahlukahlukene; kodwa-ke, uma i-L/D inkulu kakhulu, amapulasitiki azokwehliswa isikhathi sokushisa kanye nesikulufu Lapho isisindo somuntu siqu sikhula, ukuphela kwamahhala kuyaguquguquka futhi kugoqe, okubangela kalula ukuthi izinto ziklwebhe phakathi kwesikulufu nesikulufu. isikulufu, futhi yenza inqubo yokukhiqiza ibe nzima; ukusetshenziswa kwamandla kwe-extruder kuyanda. Isikulufu esifushane kakhulu singadala ukufakwa kahle kwepulasitiki kokuxova.

Ingxenye yomehluko phakathi kobubanzi obungaphakathi bomphongolo kanye nobubanzi besikulufu ibizwa ngokuthi igebe δ, elingathinta ukukhiqiza kwe-extruder. Njengoba i-δ ikhula, ukukhiqiza kuyehla. Ngokuvamile, isilawuli esingu-δ kukhethwa cishe sibe ngu-0.1 kuya ku-0.6 mm. δ incane, into esetshenziswayo ingaphansi komphumela omkhulu wokugunda, okuzuzisa ukwenziwa kwepulasitiki, kodwa δ incane kakhulu, isenzo sokugunda esiqinile sibangela kalula ukuwohloka komshini okushisayo, futhi ngesikhathi esifanayo, isikulufu silengiswa kalula noma kuhlikihlwe odongeni lwesilinda, futhi Uma u-δ emncane kakhulu, cishe akukho ukuvuza noma ukubuyela emuva kwezinto, okuthinta ukuxutshwa kokuncibilika ngezinga elithile.

I-engeli ye-helix Φ i-engeli ephakathi kwentambo nesigaba esiphambanayo sesikulufu. Njengoba i-Φ ikhula, ukukhiqiza kwe-extruder kuyanda, kodwa umphumela wokugunda namandla okucindezela epulasitiki kuyancishiswa. Ngokuvamile, i-engeli ye-helix iphakathi kuka-10° no-30 degrees. Phakathi kuka-°, lapho kushintshwa ubude besikulufu, ngokuvamile kusetshenziswa isikulufu esilinganayo, sithatha iphimbo elilingana nobubanzi, inani elingu-Φ licishe libe ngu-17 ° 41 '

Uma isilinganiso sokucindezela sikhulu, isilinganiso esikhulu sokucindezela esitholwa ipulasitiki. Uma i-groove ingajulile, ingakhiqiza izinga eliphezulu lokugunda kwepulasitiki, elizuzisa ukudlulisa ukushisa phakathi kodonga lombhobho kanye nezinto ezibonakalayo. Ukuphakama kokuhlanganiswa kwezinto kanye nokusebenza kahle kwe-plasticizing, umkhiqizo uyancipha; kunalokho, umsele ujulile. Isimo siphambene. Ngakho-ke, izinto ezizwela ukushisa (njenge-polyvinyl chloride) kufanele zisetshenziswe ngezikulufu ezijulile; kumapulasitiki ane-viscosity encibilikayo ephansi kanye nokuzinza okuphezulu kokushisa (okufana ne-polyamide), izikulufu ezikulufa ezingajulile kufanele zisetshenziswe.

1. Ukuhlukaniswa kwesikulufu

Uma okokusebenza kuya phambili ngesikulufu, kuba nezinguquko kuzinga lokushisa, ingcindezi, i-viscosity, njll. Lolu shintsho luhlukile phakathi kobude obugcwele besikulufu. Ngokwezici ezishintshayo zento esetshenziswayo, isikulufu singahlukaniswa ngokwengeza (ukuthumela) izingxenye zezinto ezibonakalayo kanye nokucindezela. Ingxenye kanye nengxenye ye-homogenization.

1. Izifunda ezintathu zamapulasitiki namapulasitiki

Amapulasitiki anezinhlobo ezimbili ze-thermosetting ne-thermoplastic. Ngemuva kokuthi amapulasitiki e-thermosetting abunjwe futhi aphulukiswe, awakwazi ukushiswa futhi ancibilike. I-athikili ebunjiwe ye-thermoplastic ingashiswa kabusha futhi inyibilikiswe kwezinye izindatshana.

Njengoba izinga lokushisa lishintsha, i-thermoplastic ikhiqiza ushintsho lwezimo ezintathu zesimo sengilazi, isimo sokunwebeka okuphezulu kanye nesimo sokugeleza kwe-viscous. Izinguquko eziphindaphindiwe ngezinga lokushisa, lezi zifunda ezintathu zikhiqiza izinguquko eziphindaphindiwe.

a. Izici ezihlukile zokuncibilika kwe-polymer ku-tri-state:

I-Glass state - ipulasitiki ibonakala njengento eqinile eqinile; Amandla okunyakaza okushisayo mancane, amandla e-intermolecular makhulu, ukuguqulwa kubangelwa ngokuyinhloko ukuguqulwa kwe-engeli yebhondi; ngemva kokususwa kwamandla angaphandle, ukuguqulwa kubuyiselwa ngaso leso sikhathi, okuyingxenye ye-deformation evamile.

Isimo esinwebeka kakhulu - ipulasitiki yinto efana nerabha; i-deformation inikezwa ukuqondiswa kwe-macromolecular stretch okubangelwa ukuqondiswa kwesigaba, futhi inani lokuguqulwa likhulu; ngemva kokususwa kwamandla angaphandle, ukuguqulwa kungabuyiselwa kodwa kuncike esikhathini, okuyi-deformation ephezulu yokunwebeka.

Isimo sokugeleza kwe-viscous-amapulasitiki avela njengokuncibilika kwe-viscous; amandla ashisayo aphinde aqinise ukunyakaza okuhlobene kwama-molecule e-chain; i-deformation ayinakubuyela emuva futhi iyingxenye ye-plastic deformation

b. Ukucutshungulwa kwePlastiki kanye ne-plastic tri-state:

Isebenza ngengilazi yepulasitiki. Ukucutshungulwa kokwelula kusesimweni sokunwebeka okuphezulu, njengokudwetshwa kwentambo, ukukhishwa kwamapayipi, ukubumba igalelo kanye ne-thermoforming. Esimeni sokugeleza kwe-viscous, ingagcotshwa, i-rotomold futhi ibunjwe ngomjovo.

Uma izinga lokushisa liphakeme kunesimo sokugeleza kwe-viscous, ipulasitiki izobola ngokushisa, futhi lapho izinga lokushisa liphansi kunesimo sengilazi, ipulasitiki izobe ifakwe embrittled. Uma izinga lokushisa lepulasitiki liphakeme kunesimo sokugeleza kwe-viscous noma liphansi kunesimo sengilazi, i-thermoplastic ivame ukuwohloka kakhulu futhi ibhujiswe, ngakho-ke izindawo ezimbili zokushisa kufanele zigwenywe lapho kusetshenzwa noma kusetshenziswa umkhiqizo wepulasitiki.

Iphrofayili yesicabha namafasitela yenziwe nge-PVC powder. I-Plastic extruder Gearbox isetshenziswa kakhulu njengephrofayili yewindi nomnyango, kanye nezinto zokuhlobisa. Ngobuchwepheshe besimanje kanye nomklamo olungiselelwe, inendawo yomthamo ophezulu wokuphuma, impilo ende kanye nepulasitiki ngokuqhubekayo.

I-Plastic extruder Gearbox iwuhlobo lomugqa wokukhiqiza oklanyelwe ukukhishwa kwe-PVC plastic doos kanye namaphrofayli ewindi kanye namapayipi ekhebula okuxhumana ahlukene, amaphrofayili ayinhlanganisela ye-Aluminium-plastic, njll. Ine-plastification ezinzile, okukhiphayo okuphezulu, amandla okushelela aphansi, isevisi yempilo ende. kanye nezinye izinzuzo. Amaphrofayili e-PVC angasetshenziswa embonini yokwakha nasekhaya noma ehhovisi.

Ukugcoba nokupholisa, ukushisa

Amagiya nama-bearings agcotshwe ngamachibi kawoyela nama-splashes. Ngaphezu kokugcotshwa kwe-splash, U-gearbox we-ZLYJ owuchungechunge oluqinile futhi ama-bearings angaphezulu angeziwe ohlelweni lokuthambisa lwepompo likawoyela ukuze kufakwe ukuthambisa okujikelezayo okuphoqelelwe.

Ibanga likawoyela wokugcoba uwoyela wegiya lokucindezela eliphakathi kwe-N220 noma amanye uwoyela wekhwalithi ephezulu wokushushuluza ane-viscosity efanayo.

Uma izinga lokushisa lendawo lingaphansi kuka-0 °C, ipayipi lokushisisa likagesi lifakwa echibini likawoyela ukuze kushiswe ngaphambili uwoyela wokugcoba.

Uma izinga lokushisa le-ambient lingaphezu kuka-35 °C, inkampani yethu yenza ukubala ibhalansi yokushisa ngokuvumelana nenani lokushisa elinikezwa umsebenzisi ukuze inqume ukuthi inyuse idivayisi yokupholisa.

I-ZLYJ series cylindrical bevel gearbox Imodeli ye-gearbox eqinile:

Imininingwane yilena: ZLYJ112, 133, 146, 173, 200, 225, 250, 280, 315, 330, 375, 420, 450; SJY224, 250, 280, 315; ZSYJ315, 375, 395, 420, 450, 560; 6E , 7E, 8E, 9E, 10E, 12E, 15E, JHM kanye namanye ama-gearbox aqondene nemboni yepulasitiki nenjoloba (angenziwa ngokwezifiso ama-gearbox amakhulu ahlukahlukene angajwayelekile).

I-screw extruder yesikulufu esisodwa somshini we-plastic extruder

Ozithobayo,

UCherry Zhang (uMnyango Wezentengiso; Miss.)

INER GROUP CO., LIMITED

Yantai Bonway Umkhiqizi Co., Ltd

Ucingo: + 86-535-6330966

Iselula: + 86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

I-Viber / Line / Whatsapp / Wechat: 008618865558975

E-mail:

Engeza: No.5 Wanshoushan Road Yantai idolobha Isifundazwe Shandong, China

Insizakalo enhle kakhulu kusuka kuchwepheshe wethu wokuhambisa udlulisela kubhokisi lokungenayo ngqo.

Inkonzo Yethu

Thola in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T + 86 535 6330966

W + 86 185 63806647