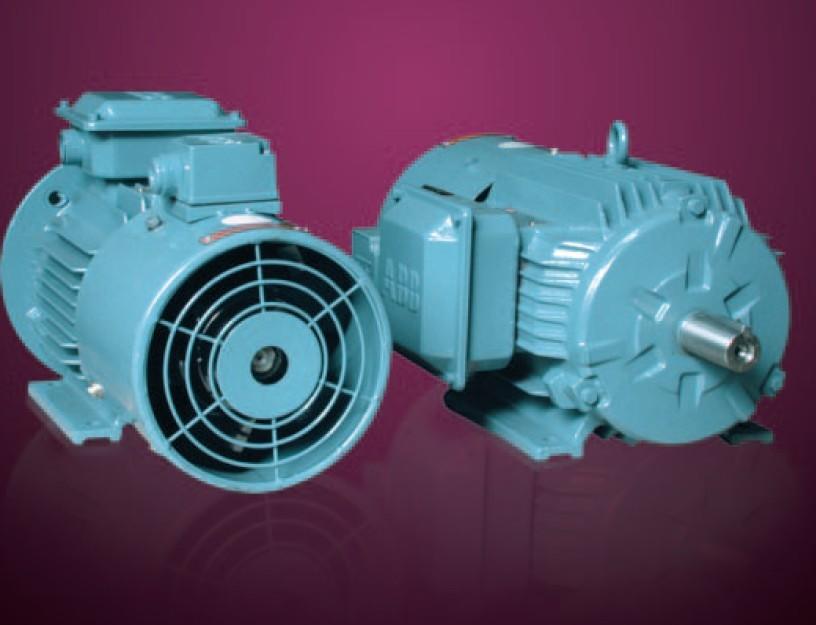

I-ABB MOTOR QABP71M2A

I-ABB MOTOR QABP71M2B

I-ABB MOTOR QABP80M2A

I-ABB MOTOR QABP80M2B

I-ABB MOTOR QABP315L4A

I-ABB MOTOR QABP315L4B

I-ABB MOTOR QABP355M4A

I-ABB MOTOR QABP355L4A

Uchungechunge lwe-QABP: Idizayini ye-variable frequency drive motor inengqondo, futhi ingafaniswa neziguquli zefrikhwensi ezifanayo ekhaya naphesheya. Iyashintshashintsha kakhulu futhi iguquguquka. Izinga lokusebenza kahle kwamandla yi-EFF2 / IE3

Uchungechunge lwesivinini esishintshashintshayo se-QABP esilawula injini sidonsa izinzuzo zemikhiqizo evela emazweni athuthukile njengeJalimane ne-Japan, futhi lisebenzisa ubuchwepheshe bomklamo osizwa ngekhompuyutha ekuklameni. Ingafaniswa nohlobo olufanayo lwedivayisi yokuguqula imvamisa ekhaya naphesheya, ngokushintshana okuqinile kanye nokwenza izinto ezihlukahlukene. I-motor ithatha isakhiwo se-squirrel-cage, esithembekile ekusebenzeni futhi kulula ukusigcina. Injini ifakwe i-axial fan ngokuhlukana ukuze kuqinisekiswe ukuthi injini inomphumela omuhle wokupholisa ngesivinini esihlukile. I-motor insulation yamukela ukwakheka kwe-F-class insulation esetshenziswa kabanzi emhlabeni wonke, okuthuthukisa ukuthembeka kwemoto. Izinkomba ezihambisanayo zamandla emoto, usayizi wokukhweza unyawo nokuphakama kwesikhungo kuhambisana ngokuphelele nochungechunge lwe-QA motors asynchronous. Lolu chungechunge lwamamotho angasetshenziswa kakhulu ezimbonini ezifana nezimboni ezilula, izindwangu, imboni yamakhemikhali, i-metallurgy, amathuluzi omshini, njll. ezidinga amadivaysi ajikelezayo alawula isivinini, futhi angumthombo wamandla ofanele wokulawula isivinini.

Amandla alolu chungechunge lwama-motor asuka ku-0.25 kW kuya ku-200 kW, futhi ukuphakama kwesikhungo sohlaka kusuka ku-71 mm kuya ku-315 mm.

Injini yokuguqula imvamisa isho injini egijima ngokuqhubekayo ngomthwalo olinganiselwe ongu-100% ebangeni lika-10% ukuya ku-100% wesivinini esilinganiselwe ngaphansi kwezimo zemvelo ezijwayelekile, futhi ukukhuphuka kwezinga lokushisa ngeke kudlule inani elivumelekile lemoto elilinganiselwe.

Ngokuthuthuka okusheshayo kobuchwepheshe bamandla kagesi kanye namadivayisi amasha we-semiconductor, ubuchwepheshe bokulawula isivinini se-AC buye bathuthukiswa futhi bathuthukiswa ngokuqhubekayo, futhi ama-inverter athuthukiswa kancane kancane asetshenziswe kabanzi kumamotho e-AC ngamagagasi awo aphumayo amahle kanye nokusebenza kahle kwezindleko. Isibonelo: ama-motor amakhulu nama-roller motors aphakathi nendawo namancanyana asetshenziswa ezigayweni zensimbi, ama-traction motors kojantshi wesitimela nezokuthutha zasemadolobheni, ama-elevator motors, ama-crane motors wemishini yokuphakamisa izitsha, ama-motor amaphampu namafeni, ama-compressor, izinto zikagesi zasendlini Ama-Motor anazo ngokulandelana. usebenzise amamotho alawula isivinini esishintshashintshayo se-AC, futhi bathole imiphumela emihle [1]. Ukwamukela injini elawula isivinini esishintshashintshayo se-AC kunezinzuzo ezibalulekile ngaphezu kwemoto elawula isivinini se-DC:

(1) Ukulawulwa kwejubane okulula nokonga amandla.

(2) I-AC motor inesakhiwo esilula, usayizi omncane, inertia encane, izindleko eziphansi, ukugcinwa okulula, nokuqina.

(3) Umthamo unganwetshwa ukuze kuzuzwe isivinini esikhulu nokusebenza kwamandla kagesi aphezulu.

(4) Iyakwazi ukubona isiqalo esithambile kanye nokubhuleka okusheshayo.

(5) Akunanhlansi, akukwazi ukuqhuma, ukuguquguquka okuqinile kwemvelo. [1]

Eminyakeni yamuva nje, ukudluliswa kokulawula isivinini sokuguqulwa kwamazwe ngamazwe kuye kwathuthukiswa ngezinga lokukhula lonyaka lika-13% kuya ku-16%, futhi kancane kancane kuthathe indawo yama-DC amaningi alawula isivinini. Ngenxa yokuthi amamotho ajwayelekile a-asynchronous asebenza ngokuvama okungashintshi kanye nokunikezwa kwamandla kagesi njalo asetshenziswa ezinhlelweni zokulawula isivinini esishintshashintshayo, kunemikhawulo emikhulu. Ama-inverter AC motors akhethekile aklanywe ngokwesikhathi sokufaka isicelo kanye nezidingo athuthukiswe phesheya. Isibonelo, kukhona amamotho anomsindo ophansi, anyakazisa kancane, amamotho anezici zetorque ezithuthukisiwe, amamotho anesivinini esikhulu, amamotho anama-tachogenerator, namamotho alawulwa yi-vector [1].

Umgomo wokwakha

Lapho izinga lokushelela lemoto e-asynchronous lishintsha kancane, isivinini silingana nemvamisa. Kungabonakala ukuthi ukushintsha imvamisa yamandla kungashintsha isivinini se-asynchronous motor. Emlawulweni wesivinini sokuguqulwa kwemvamisa, kuhlale kwethenjwa ukuthi ukugeleza kazibuthe okuyinhloko kuhlala kungashintshile. Uma i-flux kazibuthe eyinhloko inkulu kune-flux kazibuthe ngesikhathi sokusebenza okuvamile, ukujikeleza kazibuthe kugcwele ngokweqile ukuze kwandiswe amandla amanje kanye nokunciphisa isici samandla. Uma i-flux kazibuthe eyinhloko ingaphansi kokuguquguquka kazibuthe phakathi nokusebenza okujwayelekile, i-torque ye-motor iyancishiswa [1].

Ukuhlela inqubo yokuthuthukisa

Izinhlelo zamanje zokuguqula imvamisa yezimoto ziyizinhlelo zokulawula ze-V / F ezingashintshi. Izici zalolu hlelo lokulawula ukuguqulwa kwemvamisa ziyisakhiwo esilula kanye nokukhiqiza okushibhile. Lolu hlelo lusetshenziswa kakhulu ezindaweni ezinkulu njengabalandeli nalapho izidingo zokusebenza eziguqukayo zesistimu yokuguqula imvamisa zingekho phezulu kakhulu. Lolu hlelo luwuhlelo olujwayelekile lokulawula iluphu. Lolu hlelo lungakwazi ukuhlangabezana nezidingo zokudlulisela okushelelayo kwamamotho amaningi, kodwa lunomkhawulo olinganiselwe wokusebenza kokulungiswa okuguquguqukayo nokumile, futhi alukwazi ukusetshenziswa ezinhlelweni ezinezidingo eziqinile ekusebenzeni okuguquguqukayo nokumile. wendawo. Ukuze sizuze ukusebenza okuphezulu kokulawula okuguquguqukayo nokumile, singasebenzisa kuphela amasistimu okulawula amaluphu avaliwe ukuze sikufinyelele. Ngakho-ke, abanye abacwaningi baye bahlongoza indlela yokulawula isivinini semoto elawula imvamisa yokushelela kwe-loop evaliwe. Le ndlela yokulawula isivinini ingafinyelela ukusebenza okuphezulu ekulawuleni isivinini esiguquguqukayo esimile, kodwa lolu hlelo lungatholakala kuphela kumamotho anesivinini esincane. Isicelo kufanele kube ukuthi lapho isivinini se-motor siphezulu, lolu hlelo ngeke lufeze injongo yokonga amandla kuphela, kodwa futhi lubangele ukuthi i-motor ikhiqize umthamo omkhulu wesikhashana, okuzokwenza ukuthi i-torque ye-motor ishintshe ngokushesha. Ngakho-ke, ukuze sifinyelele ukusebenza okuphezulu okuguquguqukayo nokumile ngesivinini esiphezulu, kufanele siqale sixazulule inkinga yamanje yesikhashana ekhiqizwa injini. Kuphela ngokuxazulula le nkinga ngendlela efanele singakwazi ukuthuthukisa kangcono ubuchwepheshe bokulawula ukonga amandla okuguqula imvamisa yezimoto. [2]

Izici EzibalulekileHlela

Injini ekhethekile yokuguqula imvamisa inezici ezilandelayo:

Idizayini yokukhuphuka kwezinga lokushisa yekilasi B, ukukhiqizwa kwe-insulation yekilasi F. I-polymer insulation material ephezulu kanye nenqubo yokukhiqiza upende we-vacuum dip kanye nesakhiwo esikhethekile sokufakelwa kwemukelwa ukwenza ama-windings kagesi ane-insulation ephakeme ukumelana ne-voltage namandla aphezulu emishini, anele ukusebenza ngesivinini esikhulu semoto kanye nokumelana namandla aphezulu ukushaqeka kanye ne-voltage ye-inverter. Ukulimala kwe-insulation.

Ikhwalithi yebhalansi iphezulu, futhi ileveli yokudlidliza iyileveli engu-R (izinga lokudlidliza elincishisiwe). Izingxenye zemishini zinokunemba okuphezulu kwemishini, futhi kusetshenziswa ama-bearings akhethekile aphezulu, angagijima ngesivinini esikhulu.

Isistimu yokupholisa yokungenisa umoya ephoqelelwe, zonke zisebenzisa ifeni ye-axial flow engenisiwe ethule kakhulu, impilo ephezulu, umoya onamandla. Qinisekisa ukuthi injini ithola ukunqanyulwa kokushisa okusebenzayo kunoma isiphi isivinini futhi ingafinyelela ukusebenza okunesivinini esikhulu noma okuphansi kwesikhathi eside.

Uma kuqhathaniswa nama-motor inverter endabuko, ama-motor ochungechunge lwe-YP aklanywe isoftware ye-AMCAD anebanga elibanzi lejubane kanye nekhwalithi ephezulu yokuklama. Idizayini ekhethekile yamagnetic field icindezela futhi izinkundla kazibuthe ezine-harmonic ephezulu ukuze ihlangabezane nezidingo zefrikhwensi ebanzi, ukonga amandla kanye nenkomba yokuklama yomsindo ophansi. Ngohlu olubanzi lwe-torque engaguquki kanye nezici zokulawula isivinini samandla, ijubane lizinzile futhi akukho ripple ye-torque.

Ine-parameter enhle ehambisana nezinhlobo ezihlukahlukene zama-inverter, futhi ngokulawula kwe-vector, ingakwazi ukufeza i-torque engu-zero egcwele isivinini, i-torque ephansi yefrikhwensi enkulu nokulawula isivinini esinembayo, ukulawulwa kwendawo kanye nokulawulwa kokuphendula okuguquguqukayo okusheshayo. Amamotho akhethekile okuguqula imvamisa yochungechunge lwe-YP angahlonywa amabhuleki nezishumeki ukuze anikeze ukuma okunembayo, futhi azuze ukulawulwa kwesivinini okunembayo okuphezulu ngokulawula isivinini esivaliwe.

Ukwamukela "isinciphisi + ukuguqulwa kwemvamisa okunikelwe imotor + encoder + inverter" ukuze kuzuzwe ukulawula okunembile kwesivinini esingenasinyathelo esiphansi kakhulu. I-YP series inverter injini yenhloso ekhethekile inokuguquguquka okuhle, futhi ubukhulu bokufakwa kwayo buhambisana namazinga e-IEC, futhi iyashintshashintsha namamotho ajwayelekile ajwayelekile.

Ukuhlelwa kokulimala kwezimoto

Ngesikhathi sokuphromotha nokusebenzisa amamotho e-AC ahlukahlukene, kube nenani elikhulu lokulimala kwangaphambi kwesikhathi ekufakweni kwamamotho e-AC ahlukahlukene. Amamotho amaningi e-AC ahlukahlukene anempilo yesevisi engu-1 kuya kwemi-2 kuphela, kanti amanye anamasonto ambalwa kuphela. Ngisho nangesikhathi sokusebenza kwesivivinyo, ukufakwa kwezimoto kulimale, futhi kuvame ukwenzeka phakathi kokushintshana. Lokhu kuletha izinkinga ezintsha kubuchwepheshe be-motor insulation. Ukuzijwayeza kufakazele ukuthi ithiyori yokuklanywa kwe-motor insulation ngaphansi kwamandla kagesi i-sine wave voltage ethuthukiswe emashumini ambalwa eminyaka adlule ayikwazi ukusetshenziswa kumamotho alawulwa yi-AC aguquguqukayo. Kudingeka ukutadisha indlela yokulimala ye-inverter motor insulation, ukusungula ithiyori eyisisekelo ye-AC inverter motor insulation design, futhi wenze amazinga ezimboni zama-AC inverter motors.

1 Ukulimala kwezintambo zikagesi

1.1 Ukukhipha ingxenye kanye nokushaja kwesikhala

Njengamanje, amamotho we-AC alawulwa yi-variable-frequency speed-regulated alawulwa ubuchwepheshe be-IGB T (Insulated Gate Diode) PWM (Pulse width m odulatio n-pulse width modulation) inverters. Amandla ayo alinganiselwa ku-0.75 kuya ku-500kW. Ubuchwepheshe be-IGBT bunganikeza okwamanje ngesikhathi esifushane kakhulu sokukhuphuka. Isikhathi sayo sokukhuphuka singu-20 ~ 100μs, futhi i-pulse kagesi ekhiqiziwe ine-frequency yokushintsha ephezulu kakhulu, efinyelela ku-20kHz. Lapho i-voltage ekhuphuka ngokushesha isuka ku-inverter iye ekugcineni kwenjini, ngenxa yokungafani kokuphazamiseka phakathi kwenjini nekhebula, kukhiqizwa igagasi le-voltage elibonisiwe. Leli gagasi elibonisiwe libuyela kusiguquli se-frequency, bese lidala elinye igagasi elibonisiwe ngenxa yokungafani kokuphazamiseka phakathi kwekhebula nesiguquli se-frequency, esingezwe kugagasi langempela le-voltage, ngaleyo ndlela likhiqize i-voltage ye-spike emaphethelweni aholayo we-voltage wave. . Ubukhulu be-voltage ye-spike buncike esikhathini sokukhuphuka kwe-voltage ye-pulse kanye nobude bentambo [1].

Ngokuvamile, lapho ubude bentambo bukhuphuka, i-overvoltage ivela kuzo zombili iziphetho zocingo.I-amplitude ye-overvoltage ekugcineni kwemoto ikhula ngobude bekhebula futhi ijwayele ukugcwala. . Ukuhlolwa kukhombisa ukuthi i-overvoltage ivela emaphethelweni akhuphukayo nawayo we-voltage, futhi i-oscillation yokunciphisa iyenzeka. Ukuncishiswa kuthobela umthetho we-exponential, futhi isikhathi se-oscillation sikhuphuka ngobude bentambo. Kunezinhlobo ezimbili zamafrikhwensi e-PWM yokushayela i-pulse waveform. Enye imvamisa yokushintsha. Imvamisa yokuphinda ye-voltage ye-spike ilingana ngokuqondile nemvamisa yokushintsha. Enye i-frequency eyisisekelo, elawula ngokuqondile isivinini se-motor. Ekuqaleni kwefrikhwensi ngayinye eyisisekelo, i-pulse polarity iyashintsha isuka kuphozithivu iye kweyinhle noma isuke kugethivu iye kokuphozithivu. Ngalesi sikhathi, ukufakwa kwe-motor kungaphansi kwe-voltage enesilinganiso esigcwele esiyiphinda kabili inani eliphakeme kakhulu le-voltage. Ngaphezu kwalokho, enjini yezigaba ezintathu enamawindi ashumekiwe, i-voltage polarity phakathi kwamajika amabili aseduze ezigaba ezihlukene ingase yehluke, futhi ukugxuma kwe-voltage esikalini esigcwele kungase kufinyelele kabili inani eliphakeme lamandla kagesi. Ngokokuhlolwa, ukuphuma kwe-voltage waveform yi-inverter ye-PWM ohlelweni lwe-380 / 480V AC kunevelu ye-voltage elinganisiwe engu-1.2 kuya ku-1.5kV ekugcineni kwemoto, futhi ohlelweni lwe-576 / 600V AC, i-voltage waveform elinganiselwe. inani eliphakeme kakhulu le-voltage lifinyelela ku-1.6 kuya ku-1.8 kV. Kusobala kakhulu ukuthi ngaphansi kwalesi sikali se-voltage esigcwele, ukuphuma kwengxenye ye-surface kwenzeka phakathi kokuphenduka kwama-winding. Ngenxa ye-ionization, izindleko zesikhala zizokhiqizwa esikhaleni somoya, futhi inkambu kagesi eyenziwe ngokuphambene nensimu kagesi esetshenzisiwe izokwakhiwa. Lapho i-voltage polarity ishintsha, le nkambu kagesi ehlehlayo isendaweni efanayo nekagesi esetshenziswayo. Ngale ndlela, insimu ephakeme kagesi ikhiqizwa, okuzoholela ekwandeni kwenani lokukhishwa okuyingxenye futhi ekugcineni kubangele ukuwohloka. Ukuhlola kubonise ukuthi ubukhulu bokushaqeka kukagesi okusebenza kulokhu kushintshwa kwe-turn-to-turn kuncike ezicini ezithile zomqhubi kanye nesikhathi sokukhuphuka kwedrayivu yamanje ye-PWM. Uma isikhathi sokukhuphuka singaphansi kuka-0.1 μs, u-80% wamandla azokwengezwa ekuphendukeni okubili kokuqala kokuphenduka, okungukuthi, isikhathi sokuphakama sibe mfushane, kukhulu ukushaqeka kukagesi, kanye nempilo ye-inter ibe mfushane. -turn insulation [1].

1.2 Ukushisisa kokulahlekelwa yi-Dielectric

Uma u-E edlula inani elibalulekile le-insulator, ukulahlekelwa kwayo kwe-dielectric kukhula ngokushesha. Lapho imvamisa yanda, ukukhishwa okuyingxenye kuzokwanda ngokufanele, futhi ngenxa yalokho, ukushisa kuzokwenziwa, okuzobangela ukuvuza okukhulu kwamanje, okuzokwenza ukuthi i-Ni ikhuphuke ngokushesha, okungukuthi, ukunyuka kwezinga lokushisa kwemoto kuzokhuphuka, futhi i-insulation izoguga ngokushesha. Ngamafuphi, ku-variable frequency motor, kungenxa ngqo yemiphumela ehlanganisiwe yokukhipha ingxenye eshiwo ngenhla, ukushisisa nge-dielectric, ukungeniswa kwe-space charge kanye nezinye izici ezibangela ukulimala ngaphambi kwesikhathi kocingo luka-electromagnetic [1].

2 Ukulimala kwe-insulation eyinhloko, ukufakwa kwesigaba kanye nopende wokufakelwa

Njengoba kushiwo ngaphambili, ukusetshenziswa kwamandla okuguquguquka kwe-PWM okuguquguqukayo kukhulisa i-amplitude ye-oscillating voltage kumatheminali e-variable frequency motor. Ngakho-ke, i-insulation eyinhloko, ukufakwa kwesigaba kanye nopende we-insulating we-motor ukumelana namandla aphezulu kagesi. Ngokokuhlola, ngenxa yomphumela ohlanganisiwe wezici ezifana nesikhathi sokukhuphuka kwe-voltage, ubude bekhebula, kanye nemvamisa yokushintsha kwetheminali ephumayo ye-inverter, i-voltage ephezulu yetheminali engenhla ingadlula u-3kV. Ngaphezu kwalokho, lapho ukukhishwa okuyingxenye kwenzeka phakathi kokuphenduka kwama-motor windings, amandla kagesi agcinwe ku-capacitance esabalalisiwe ku-insulation azoba ukushisa, imisebe, amandla emishini kanye namakhemikhali, okuzokwehlisa lonke uhlelo lokufakelwa kabusha futhi kunciphise i-voltage yokuphuka. ye-insulation, ekugcineni okuholela kuhlelo lokufakwa kwe-insulation laphulwa [1].

3 Ukuguga okusheshisiwe kokufakwa ngenxa yengcindezi eshintshashintshayo yomjikelezo

Isebenzisa amandla okuguqula imvamisa ye-PWM, ukuze injini yokuguqula imvamisa iqale kumafrikhwensi aphansi kakhulu, i-voltage ephansi futhi ayikho i-inrush current, futhi ingasebenzisa izindlela ezahlukahlukene ezinikezwe isiguquli semvamisa ukwenza ukubhuleka ngokushesha. Ngenxa yokuthi injini yefrikhwensi eguquguqukayo ingafinyelela ukuqalisa kanye nokubhuleka njalo, ukufakwa kwe-motor kuvame ukuba ngaphansi komphumela we-cyclic alternating stress, futhi ukufakwa kwe-motor kuyasheshiswa ukuya eminyakeni yobudala [1].

Izinkinga zokudlidliza okubangelwa amandla okuvusa i-electromagnetic kanye nokudluliswa kwemishini kumamotho ajwayelekile angama-asynchronous ziba nzima kakhulu kumamotho ahlukahlukene. Ama-harmonics ezikhathi ezahlukahlukene aqukethwe kumandla aguquguqukayo aphazamisa ukuhambisana kwendawo okukhona engxenyeni ye-electromagnetic ukuze akhe amandla ahlukahlukene e-electromagnetic excitation. Ngesikhathi esifanayo, ngenxa yokuthi i-motor inebanga elibanzi lokusebenzisa imvamisa kanye noshintsho olukhulu lwesivinini, i-resonance iyenzeka uma ihambisana nemvamisa yemvelo yengxenye yomshini. Ngaphansi kwethonya lamandla kagesi avusa amadlingozi kanye nokudlidliza komshini, ukufakwa kwezimoto kungaphansi kwengcindezi ephindaphindekayo yokushintshashintsha kwe-cyclic, esheshisa ukuguga kwe-motor insulation.